Revolutionizing Industrial Efficiency with Tripak: The Future of Lubrication Technology

Introduction: The Power of Advanced Lubrication

In the fast-paced world of industry today, efficiency and reliability are essential. Whether you manage a manufacturing facility, logistics, or operate heavy equipment, one crucial but often overlooked aspect of performance is lubrication.

Inadequate lubrication can lead to increased wear, energy waste, equipment failures, and costly downtime. That’s where Tripak comes in as a transformative force. The company has developed advanced lubrication solutions that significantly enhance machine lifespan, operational efficiency, and savings.

This comprehensive guide will cover:

✅ The effect of lubrication on machine performance

✅ Tripak’ innovative lubrication technology

✅ Advantages of using high-performance lubricants

✅ Reasons why industrial leaders rely on Tripak for efficiency and savings.

The Role of Lubrication in Industrial Performance

Lubrication plays an essential role in industrial machinery, vehicles, and even everyday mechanical systems. Here’s why:

1. Reducing Friction & Wear

Friction is the number one enemy of machinery. Over time, constant metal-to-metal contact leads to excessive heat, surface degradation, and component failure. High-performance lubricants form a protective barrier that minimizes direct contact, preventing damage and improving performance.

2. Enhancing Energy Efficiency

Did you know that poor lubrication can increase energy consumption by up to 30%? Excess friction forces machines to work harder, consuming more fuel or electricity. Proper lubrication ensures smoother operation, reducing energy waste and carbon emissions. (Source: Energy.gov).

3. Preventing Overheating & Equipment Breakdown

Unlubricated or poorly lubricated machinery tends to overheat quickly, leading to severe failures. Using Tripak’ advanced lubricants helps regulate temperature and prevent system breakdowns, reducing maintenance costs and unplanned downtime.

4. Extending Equipment Lifespan

Replacing industrial equipment is costly and time-consuming. Regular lubrication significantly extends the life of components, such as gears, bearings, chains, and hydraulic systems, reducing the need for frequent replacements.

(Further Reading: Predictive Maintenance with Smart Lubrication)

Introducing Tripak: A New Era of Lubrication Technology

What Sets Tripak Apart?

Tripak has redefined high-performance lubrication by engineering formulas that go beyond traditional lubricants. Unlike conventional oils and greases that break down under extreme conditions, Tripak lubricants are designed to withstand harsh industrial environments, heavy loads, and high-speed operations.

✅ Key Innovations Behind Tripak Lubricants:

1️⃣ Superior Wear Protection – Extends component lifespan by preventing micro-wear.

2️⃣ Heat Resistance – Withstands extreme temperatures without breaking down.

3️⃣ Friction-Reducing Nanotechnology – Enhances efficiency for smoother operation.

4️⃣ Long-Lasting Performance – Reduces the frequency of re-application.

5️⃣ Eco-Friendly Formulation – Designed with sustainability in mind.

By incorporating these features, Tripak lubrication solutions ensure maximum performance, cost efficiency, and environmental benefits.

The Industries That Benefit Most from Tripak Lubricants

Tripak lubricants are not just for industrial giants—they benefit a wide range of industries:

🔧 Manufacturing & Heavy Machinery

Factories and industrial plants rely on high-speed production lines and robotic automation. Poor lubrication can cause equipment failures, slowing down operations and reducing output. Tripak ensures uninterrupted, high-efficiency performance.

🚚 Automotive & Transportation

Fleets of trucks, buses, and delivery vehicles require constant maintenance to remain operational. Tripak lubricants minimize engine wear, improve fuel efficiency, and extend service intervals—saving businesses thousands in repair costs.

(Check out: Best Practices for Fleet Maintenance).

🏗️ Construction & Mining

Bulldozers, excavators, and cranes endure intense pressure and extreme weather conditions. Using Tripak’ industrial-grade lubricants ensures reliability and safety in demanding construction projects.

Key Benefits of Using Tripak Lubricants

If you're still wondering why businesses worldwide are switching to Tripak, let’s break down the key advantages:

💰 1. Cost Savings on Maintenance & Repairs

💡 Fact: 70% of mechanical failures are caused by improper lubrication!

By using Tripak’ high-performance lubricants, businesses save thousands in repairs and downtime costs.

⚡ 3. Increased Operational Efficiency

Smoother-moving parts mean less energy waste, leading to faster production cycles and higher productivity.

(Learn more: Optimizing Machinery Performance)

How to Integrate Tripak Lubrication into Your Operations

Step 1: Conduct a Lubrication Audit

✅ Identify machinery that suffers from excessive wear, heat buildup, or friction issues.

✅ Assess the effectiveness of your current lubrication strategy.

Step 2: Choose the Right Tripak Lubricant

Different applications require different formulations. Consult Tripak’ product guide to select the best lubricant for your specific needs.

Final Thoughts: Why Tripak is the Ultimate Lubrication Solution

A poor lubrication strategy leads to wasted resources, unnecessary expenses, and costly equipment failures.

With Tripak, you get:

✔ Superior protection against friction and wear

✔ Enhanced machine efficiency & longevity

✔ Lower maintenance costs and downtime

✔ Environmentally friendly, high-performance lubrication

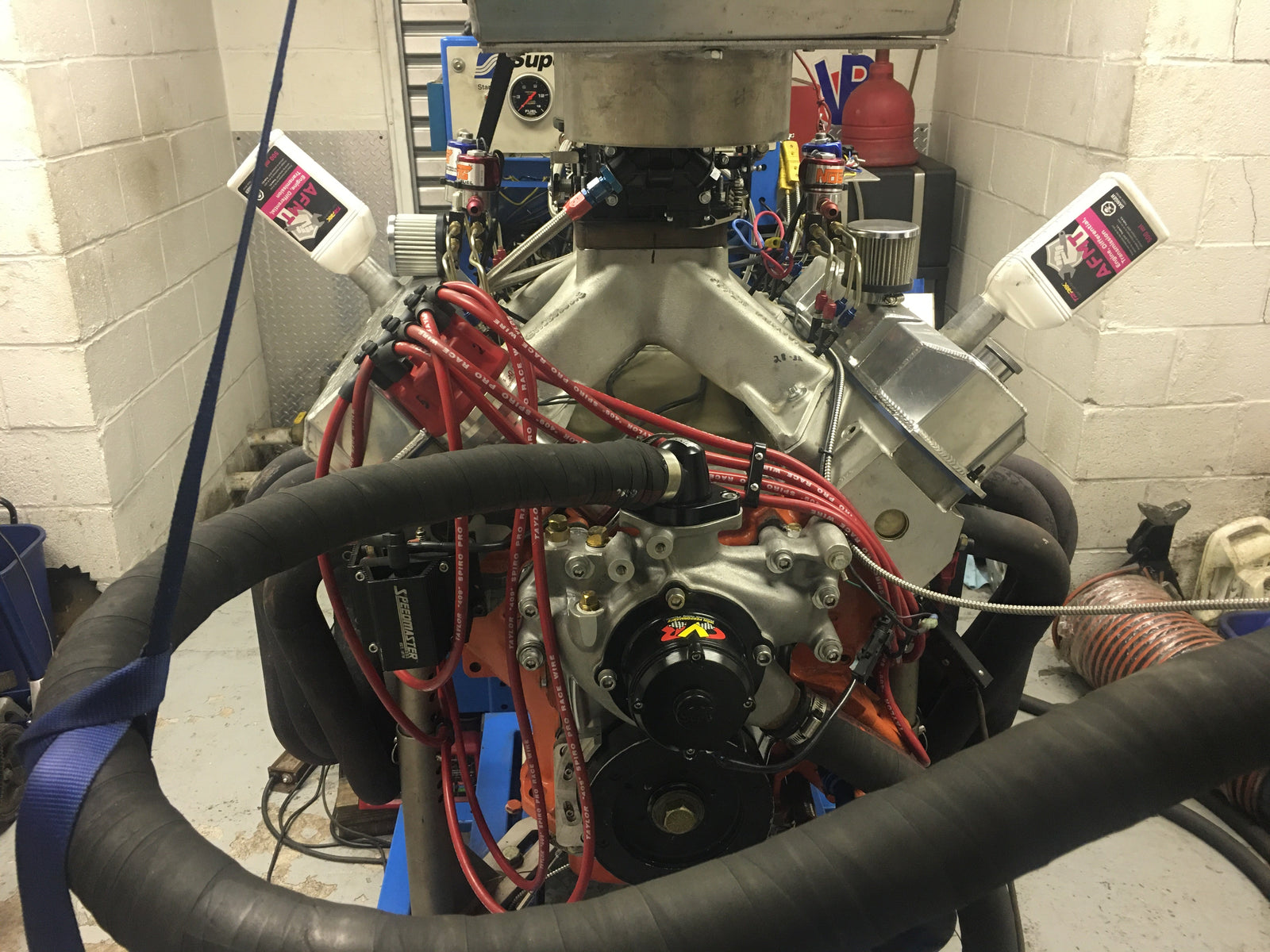

You don't have to take our word for it; watch this video demonstrating how the TRIPAK AFMT treats metal surfaces and minimizes friction.

🚀 Ready to optimize your operations? Visit Tripakus.com today!